What is flashing?

Flashing, made from either metal or a rubber membrane, is a part of the system that keeps water from entering through holes created in your roof. All roofs have penetrations: openings or holes in the roof surface which allow for elements like chimneys, flues, skylights and vents. These necessary holes in the roof, if they're not properly sealed, can become an entry point for moisture.

'Flashing' is the barrier that's installed around penetrations to keep the roof secure and sealed off from moisture.

What is flashing made of?

Flashing can be composed of many different materials, but is normally made from a metal like aluminium, copper, painted galvanised steel, stainless steel, zinc alloy, terne metal, lead or lead-coated copper. Non-metal flashing can be made of bituminous fabric or plastic sheet material.

How is flashing installed?

When installing flashing, care should be taken to protect the flashing from reacting with other roofing materials. If metal flashing comes into contact with metal roofing materials, galvanic corrosion is likely to occur, causing rust stains and metal decay.

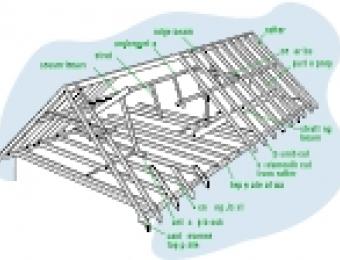

In the scheme of roofing construction, flashing is installed quite late. Once the roof frame is in place, roofing felt or some other type of waterproof membrane is installed, with holes made to accommodate for any penetrations.

Flashing is then nailed or stapled into place around the penetrations. The gaps between the penetration and the flashing are sealed, as are the gaps between the waterproof membrane and the flashing. The gaps are sealed with glue, caulk or waterproof cement - which can also interact with metal roofing and cause corrosion. Ideally, roof cladding is installed after flashings have gone in.