Electrical cabling and fittings are installed differently, depending on the wall materials you're using. The vast majority of homes in Australia are build using either timber or steel frames and plasterboard walls, but many also make use of different materials, including brick, straw bale and structural insulated panels (SIPs). Whatever you use, there's one very important rule when it comes to planning your electrical installation: get it right the first time!

Proper planning saves money

Planning is critical to having the lowest cost electrical installation. See it for a moment from the electrical contractor’s viewpoint. They will quote on the basis of specifwied requirements - any change thereafter, especially if they've already started the job or have completed it, will cost you. Work done after you've already agreed on a final cost won’t necessarily be charged on the same competitive price basis either - and with good reason!

In a conventional timber or steel framed home, the best time to install the wiring is in the framing stage. Once the walls are up and plastered, everything gets so much more cumbersome. With an accurate electrical plan the wires for power points and lighting can be pulled through to where they will have to be and allowance for this can be made as the plaster sheets are being put up. The time to get the ‘sparky’ on the job is virtually as soon as the house structure is in place.

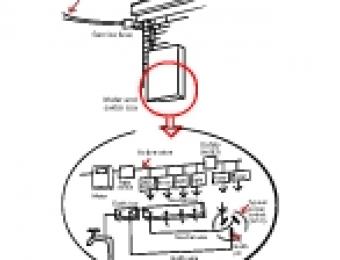

The electrician lays the wiring between the point of supply (service fuse) and the outlets according to an accurate diagram showing, at a minimum, the location of GPOs, switches and light fittings - as well as location of fixed plant like your stove/oven tops and your hot water service.

SIPS and other materials

Getting your planning right before building starts is especially important for materials that are less forgiving or not as easily repaired as plasterboard. Structural insulated panels (SIPs) are a great example. SIPs are solid, and filled with a hard foam. In order to install channels to run electrical cables through, a ball bearing may be heated up and dropped through the foam, allowing it to melt a path - or the panels may need to be specially cut for this purpose. Either way, there's not a great deal of room for error, and late changes can make a mess.