What are SIPs made from?

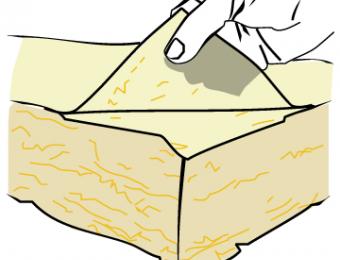

Structural insulated panels (or SIPs for short), are made from a layer of polymer foam sandwiched between two rigid panels. The foam layer can be made from either expanded polystyrene foam (EPS), extruded polystyrene foam (XPS) or polyurethane foam. The outer panel layers are typically made from either sheet metal, cement sheets, plywood or oriented strand board (OSB), or a similarly rigid material.

This forms a composite board that works on the same design principle as a steel I-beam, with the rigid panels doing the work of the flanges and the foam acting as the web. These panels can be used for the floor, walls and roof of a house, creating a perfect seal along all edges.

How do SIPs insulate a house?

The sandwiched layer of foam in the middle is what does most of the insulating work; the millions of tiny air bubbles trapped in the foam stop the transmission of heat through the SIP, though there is some thermal resistance added from the rigid panels as well. Another benefit with SIPs is that there's no framework required for a house constructed with SIPs. This means there is no chance of thermal bridges being formed. As a result, SIPs often outperform other types of insulation with a similar R value which are compromised by heat sneaking in through the house's framework.

How effective are SIPs for thermal insulation?

Because the effectiveness of SIPs varies according to the inner foam filling, the types of panels used and the overall thicknesses of the SIP, R-values can vary widely between different products.

It's common for floor, wall and roof SIPs to have different R values, with the highest ratings found on roof panels (due to the fact that heat rises). A SIP building has many other advantages though that can cut heating and cooling costs; the building envelope for these types of buildings is practically airtight, which can cut the need for heating and cooling by up to 50%. SIP buildings don't require framework, so no thermal bridging can occur through the lower R-value wood framing or steel framing either.

How much soundproofing do SIPs offer?

Again, the specific values for acoustic insulation will vary depending on the thicknesses of the materials and which materials are used. Users generally report that high frequency noises like conversation and footsteps and lower frequency sounds like the bass from music are dampened quite effectively.

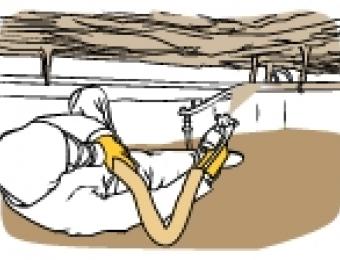

How are SIPs supplied and installed?

Structural insulated panels are supplied to the building site on a pallet, custom cut and ready to be fitted together. Since installation of SIPs replaces the need for framework, separate insulation and sometimes even the need for an interior covering such as plasterboard, the actual construction takes very little time. Some companies boast of being able to put up an entire house worth of walls in one day, with most SIPs setups being completed within a week.

What do SIPs cost?

While SIPs are obviously going to be more expensive than say, the equivalent surface area of bricks, they have many payback opportunities on investment. With little to no framework required, no need for additional materials and labour beyond putting the SIPs up, and the longer term energy savings you can expect, SIPs may well make up for the initial difference in the cost of materials (depending on the house).

Special considerations

While structural insulated panels have been on the market for some time in the US and Europe, they have only recently begun to make headway here in Australia. There are quite a few local suppliers and builders that have been in the market for a few years now though, so the construction expertise is there and more and more homes are being made from SIPs every day.