Concrete sheeting can be used on beam and joist floors instead of particle board flooring as a base for another overlay such as tiles, carpet or slate. They are especially suited to heavy flooring types as they can withstand a lot of weight without cracking. The sheets are made of fibre concrete which has added cellulose fibres for tensile strength. This allows the sheets to be thinner and remain stable. Sheets vary in thickness and density - higher thickness and density sheets will insulate sound and heat much better than lower ones, though additional insulation is often needed.

Because they don't rot or absorb moisture, they're very commonly used in laundries, kitchens and bathrooms areas.

What should I look for when choosing concrete sheeting?

The thickness of the sheets you choose will have a direct effect on the weight capacity of the finished floor. Higher fibre content is also recommended for added tensile strength, as the floor will move with time and the sheets will come under different pressures and strains.

- While there are many different options and variations available, the most common thicknesses for cement sheeting are generally either 15mm (for floors with joists spaced 450mm apart) or 18mm (for floors with joists spaced 600mm apart).

How is it installed?

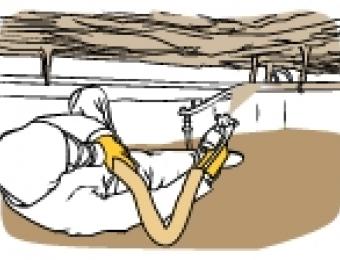

Concrete sheets are fragile before installation so extra care must be taken not to break the sheets in transit. They are heavy, and normally require a couple of sets of hands to put them in place. Sheets are cut with a mechanical saw or fibro cutter to fit the required area, including holes for plumbing where needed. A mask is normally required when cutting cement sheeting, because the fine particles that are released in the process are dangerous to inhale.

Once cut and put in position, the sheets are held in place and nailed to the joists to create a base for the floor covering. The gaps between sheets should leave adequate room for expansion to avoid cracking. It is not a good idea to paint or seal concrete sheeting, as this can affect how the covering will adhere to the surface of the sheets.

Suitability and maintenance

Concrete sheeting is often used in areas where wooden alternatives may be subject to moisture absorption, rot or termites. This makes it perfect for wet areas like bathrooms and kitchens, especially where you would expect tiles to be overlaid. While it's particularly suitable for those areas, there's no reason it can't be used throughout the whole house.

Once installed, cement sheets shouldn't require any ongoing maintenance.

|

Advantages

|

Disadvantages

|